Overview

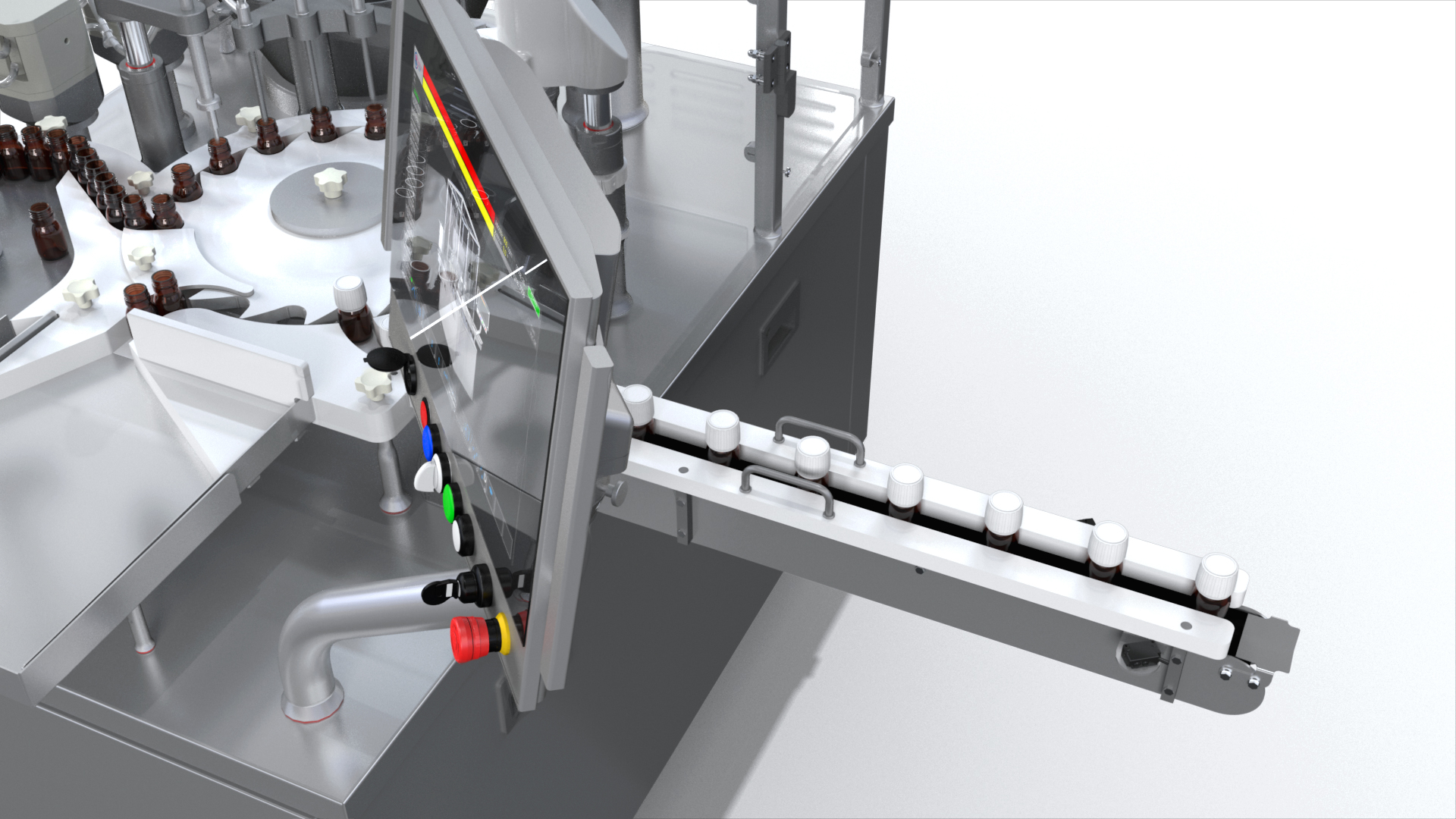

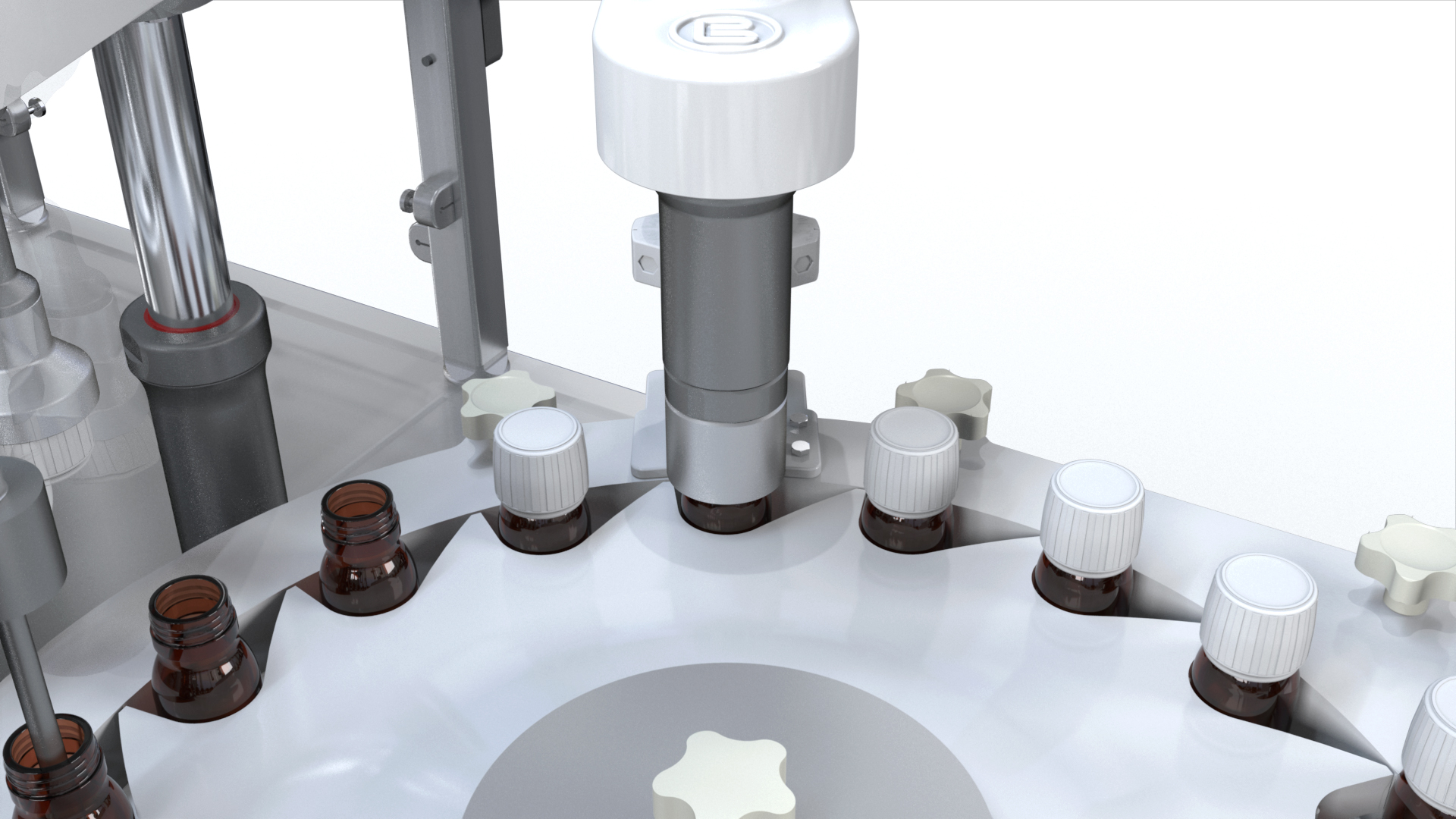

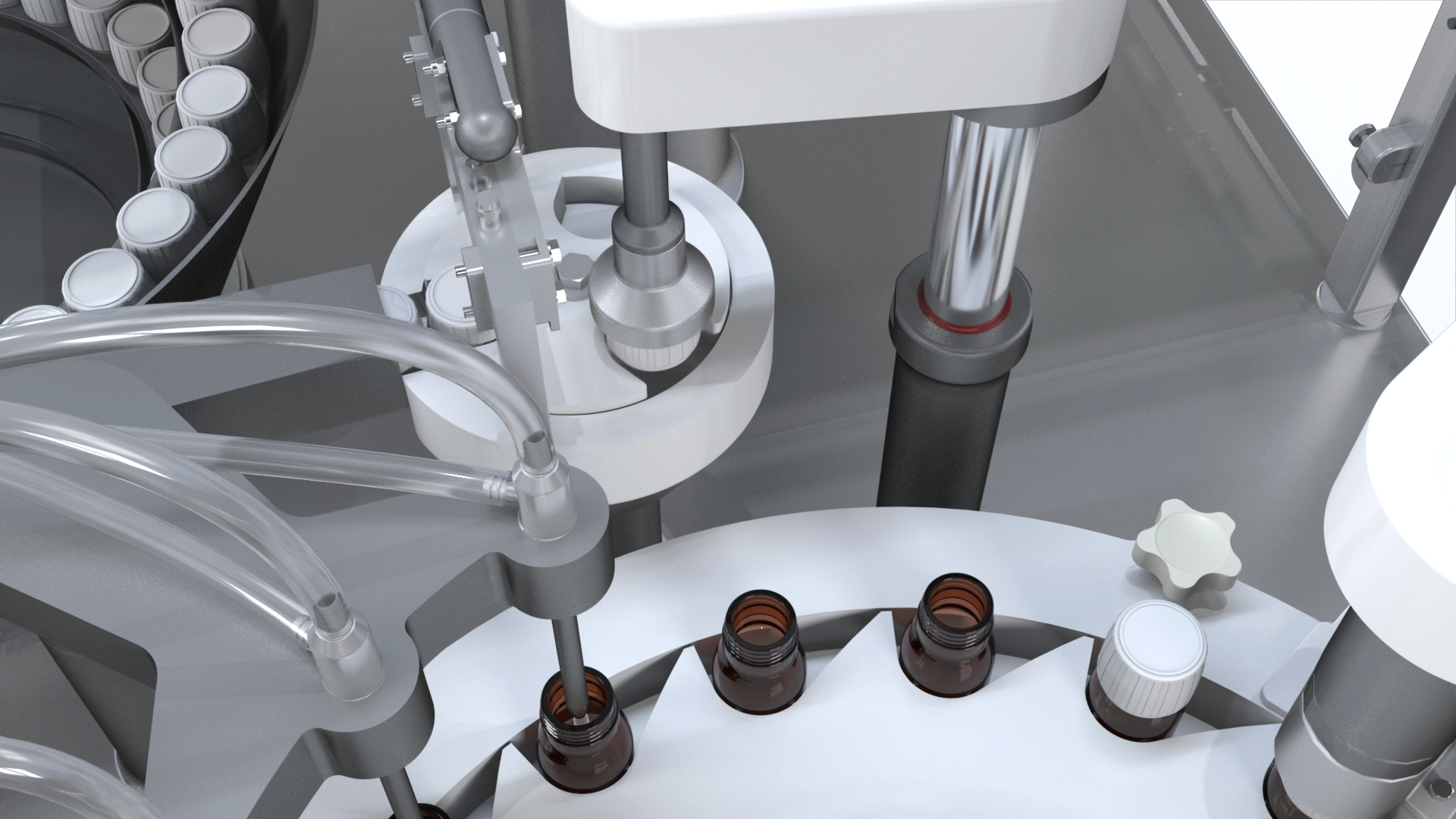

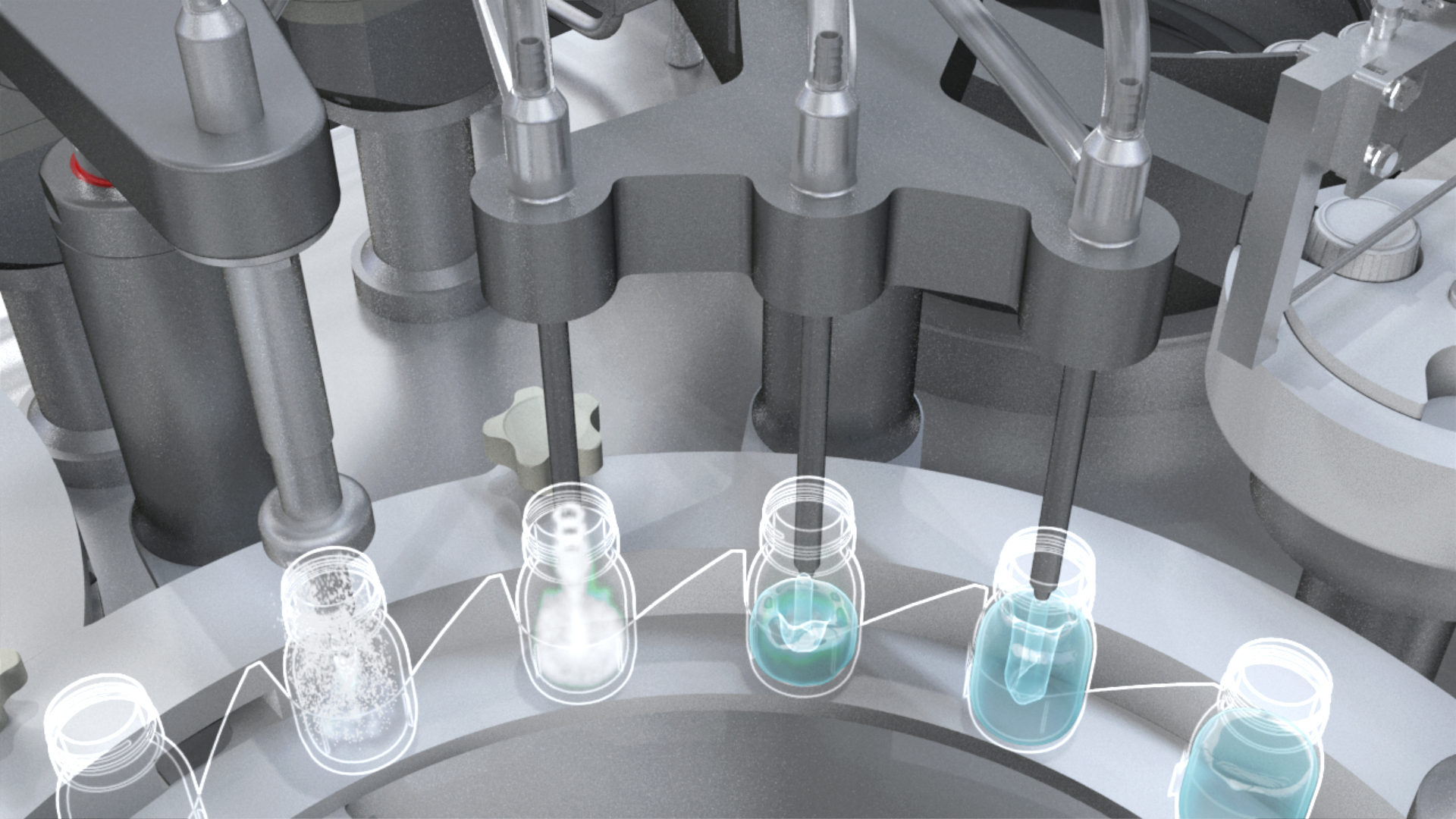

PBL Pharma Division custom designed, built, and successfully commissioned a machine for non-injectable products in glass and plastic containers with different type of container closures. The machine consists of air-blowing and aspiration stations, nitrogen purging system, filling system, capping system. Every unit is fully integrated for maximum productivity.

The machine was designed according to the customer container type and the requirements for production controls.

Each production process uses state-of-the-art equipment.

Certified ISO 7 and ISO 5 using validated processes that are constantly monitored and controlled.

Main features

⦁ Customizable loading/unloading system

⦁ IPC control (100% or statistical)

⦁ CIP/SIP system

⦁ Air blowing and vacuum station available

More features

⦁ Different filling options available

⦁ Different container closure system available

⦁ Different monitoring functions (eg. Monitoring of fill volume, seal integrity, etc)

⦁ User-friendly and fast tool-free format change

⦁ Designed as a modular machine

⦁ Custom-designed system

Machine Output

20 to 400 BpM

Compatible containers

Contact us