Overview

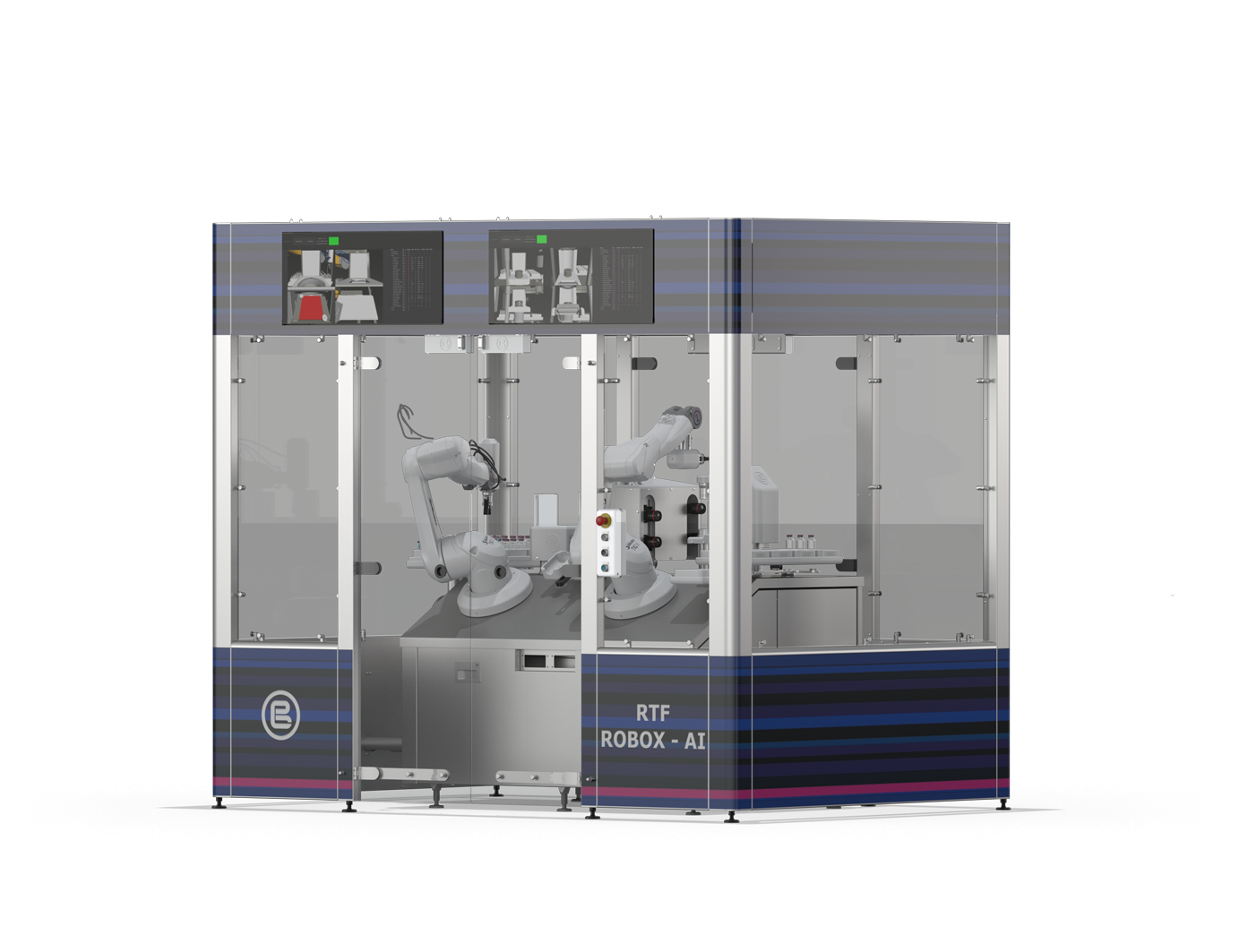

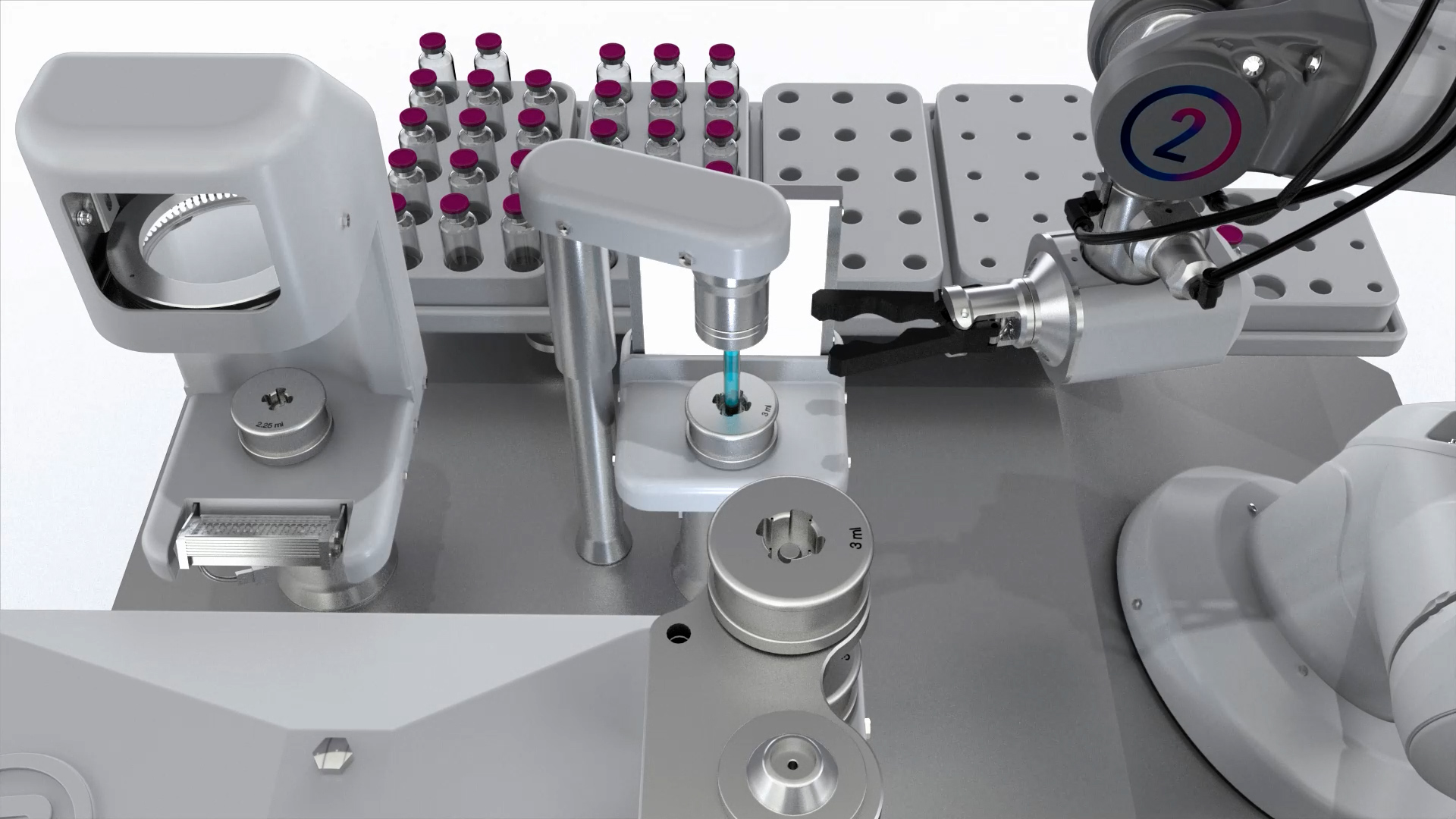

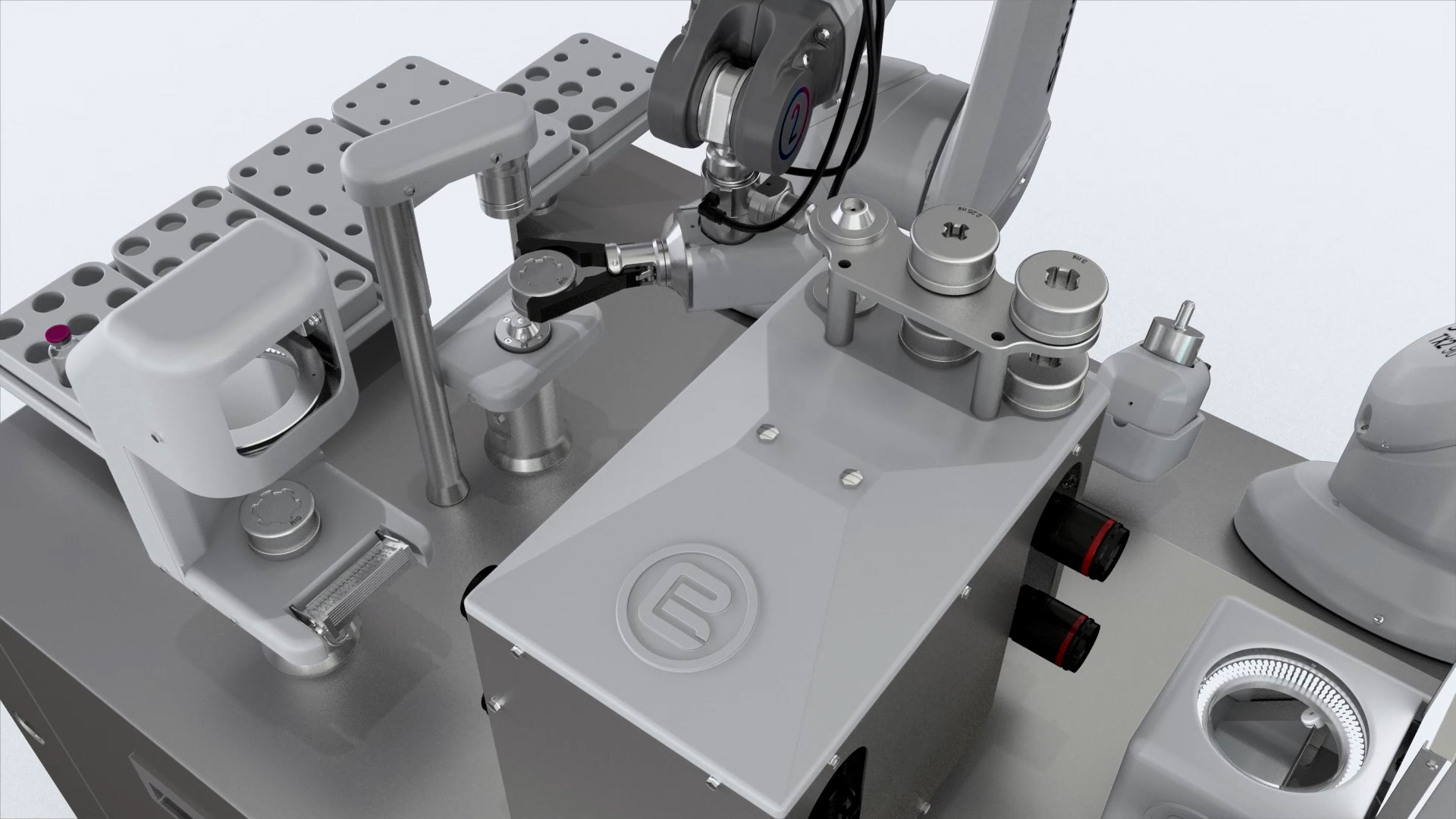

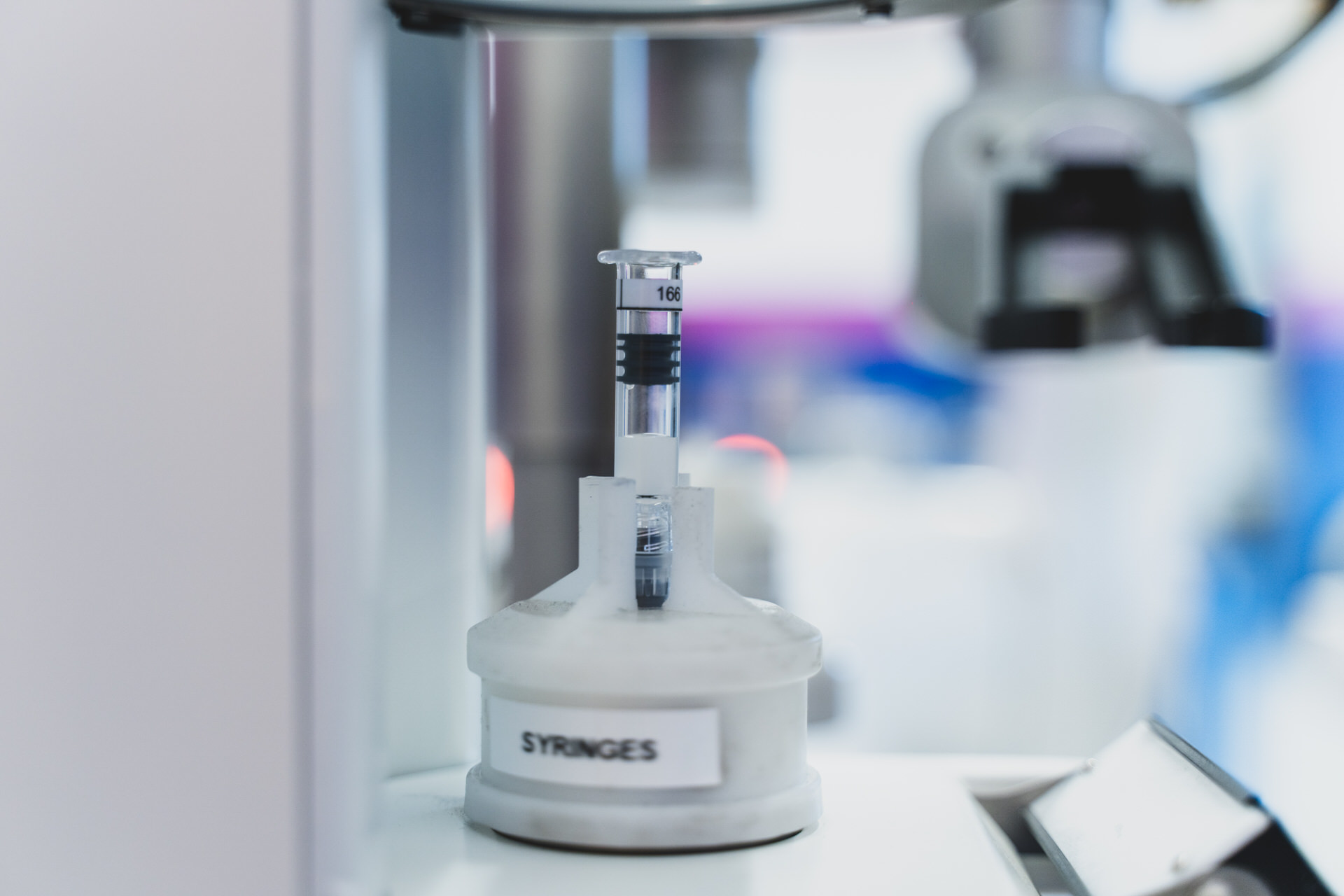

Our Pharma Division of PBL offers innovative and flexible custom designed inspection machine for all types of Ready-To-Fill (RTF) containers.

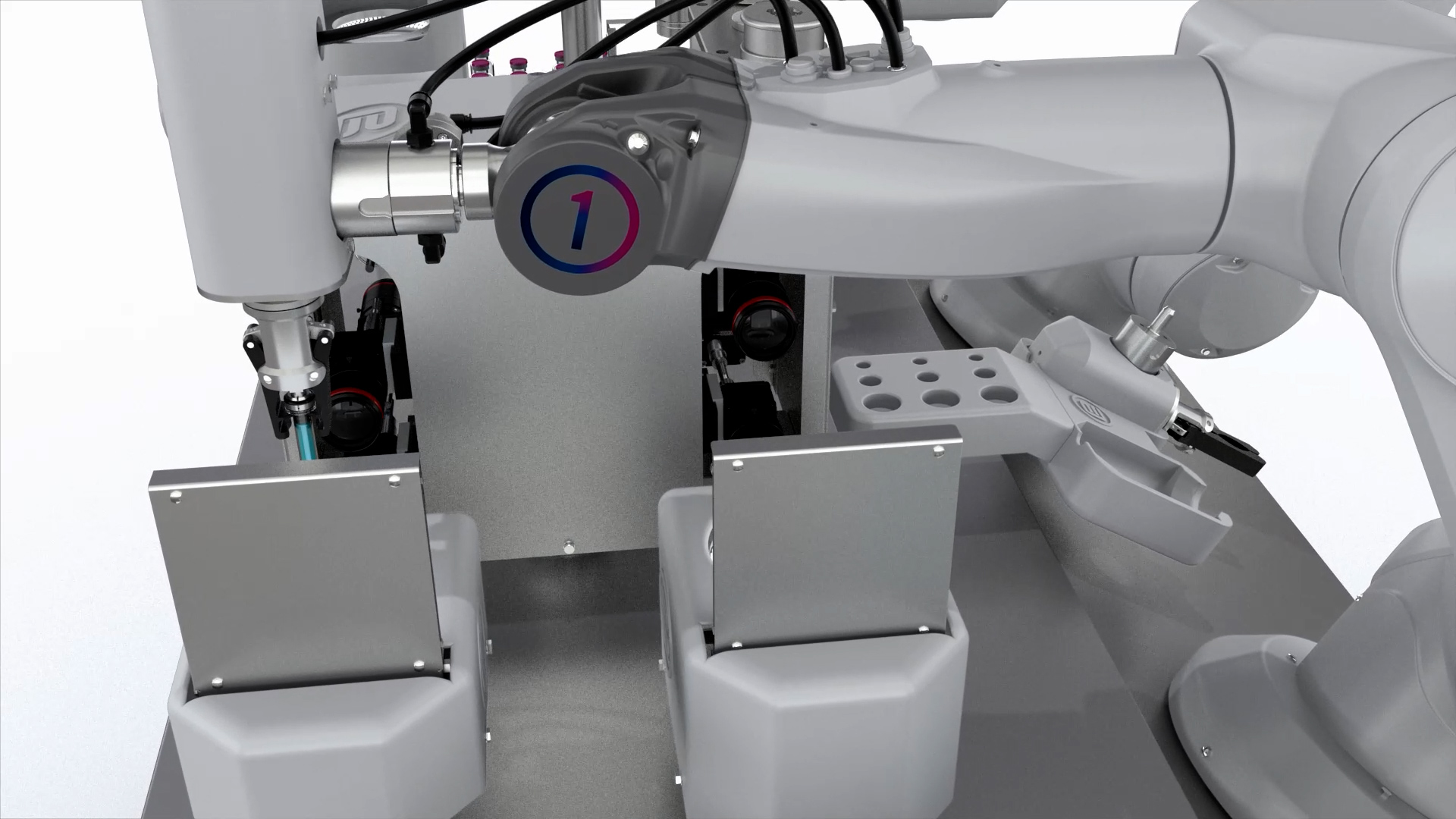

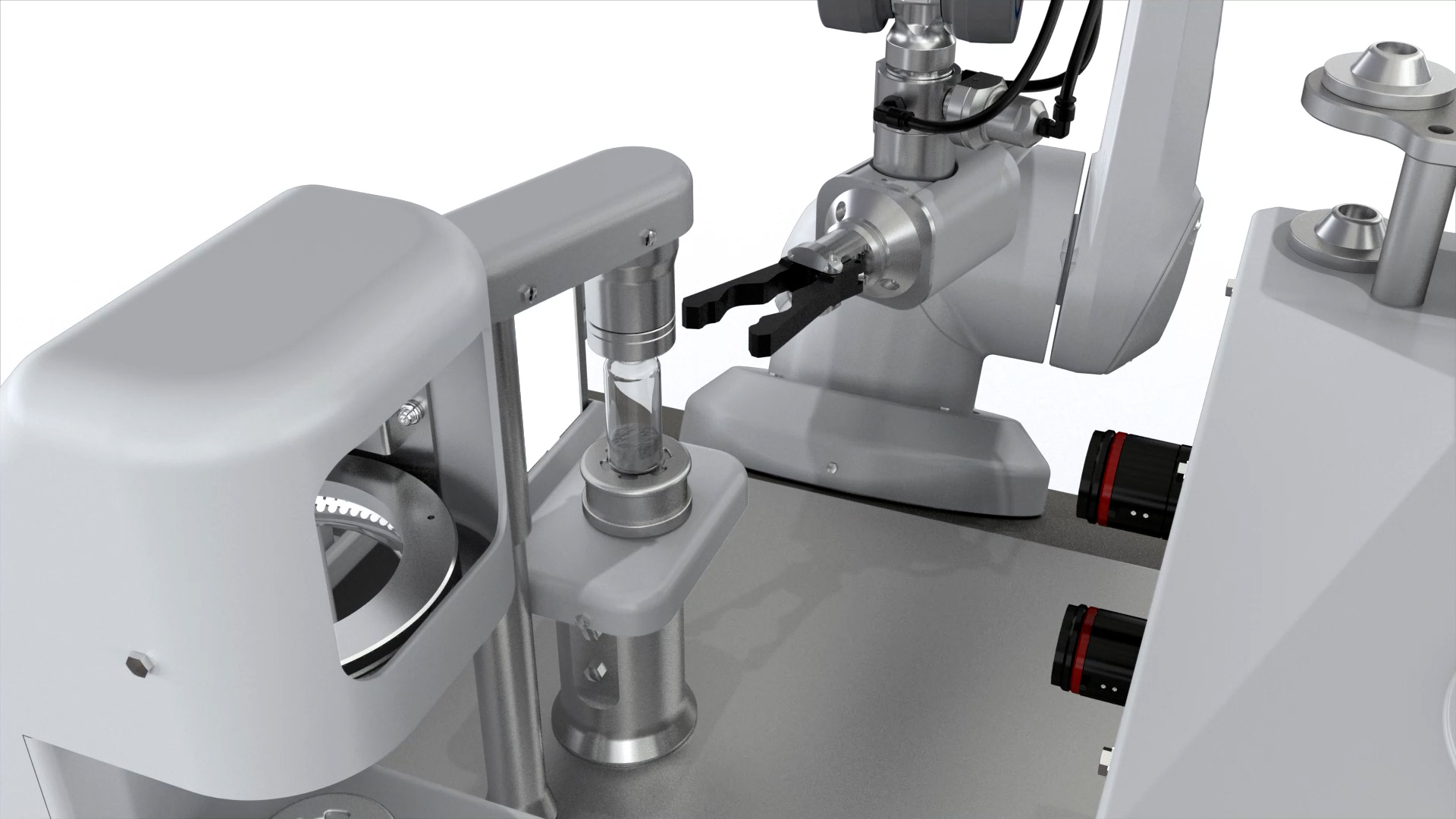

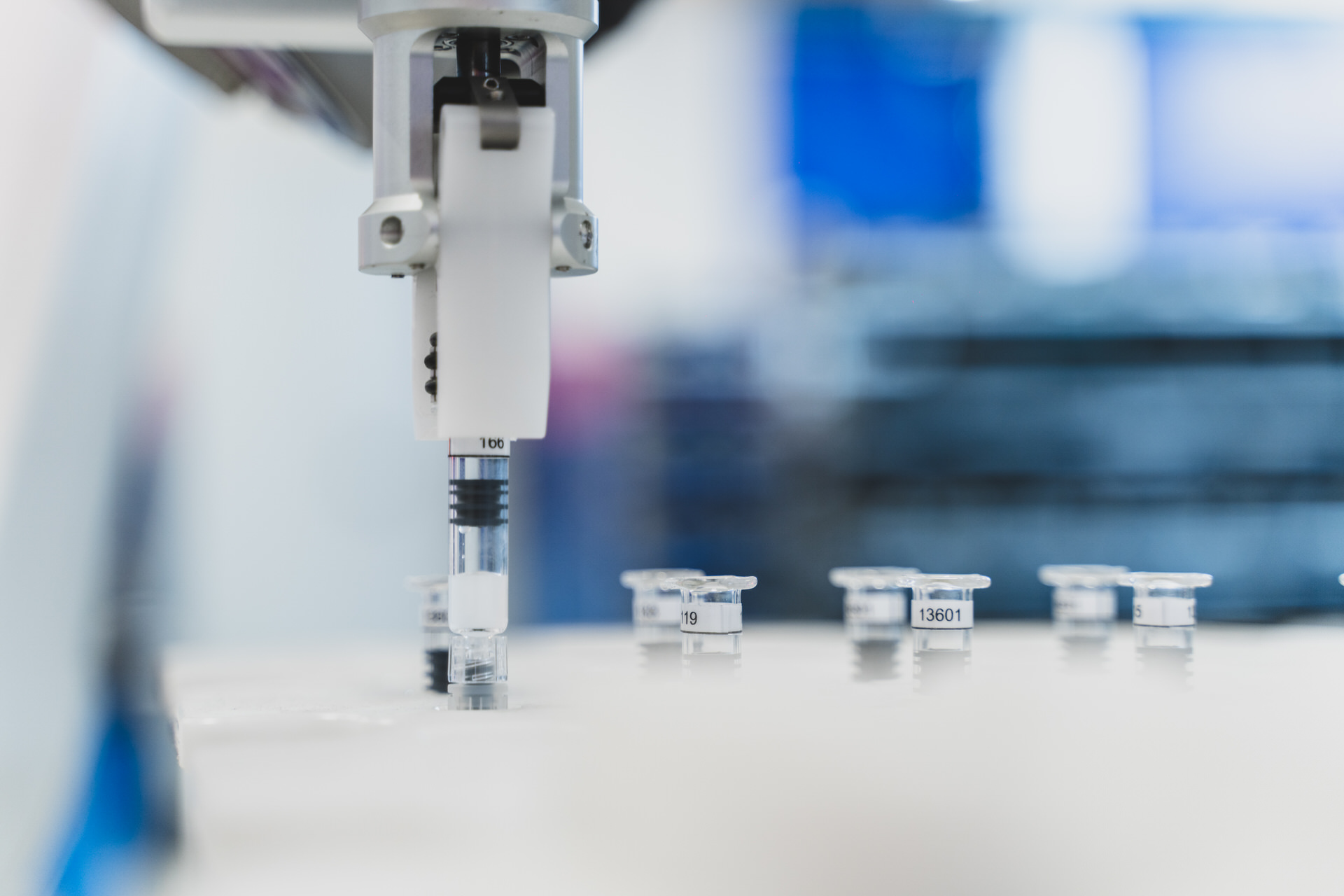

The main objective was to create a machine which, by means of cameras supported by Artificial Intelligence, could inspect different types of containers such as vials, syringes and cartridges; and with the integration of a fully automatic format changeover, in order to remove any operator intervention.

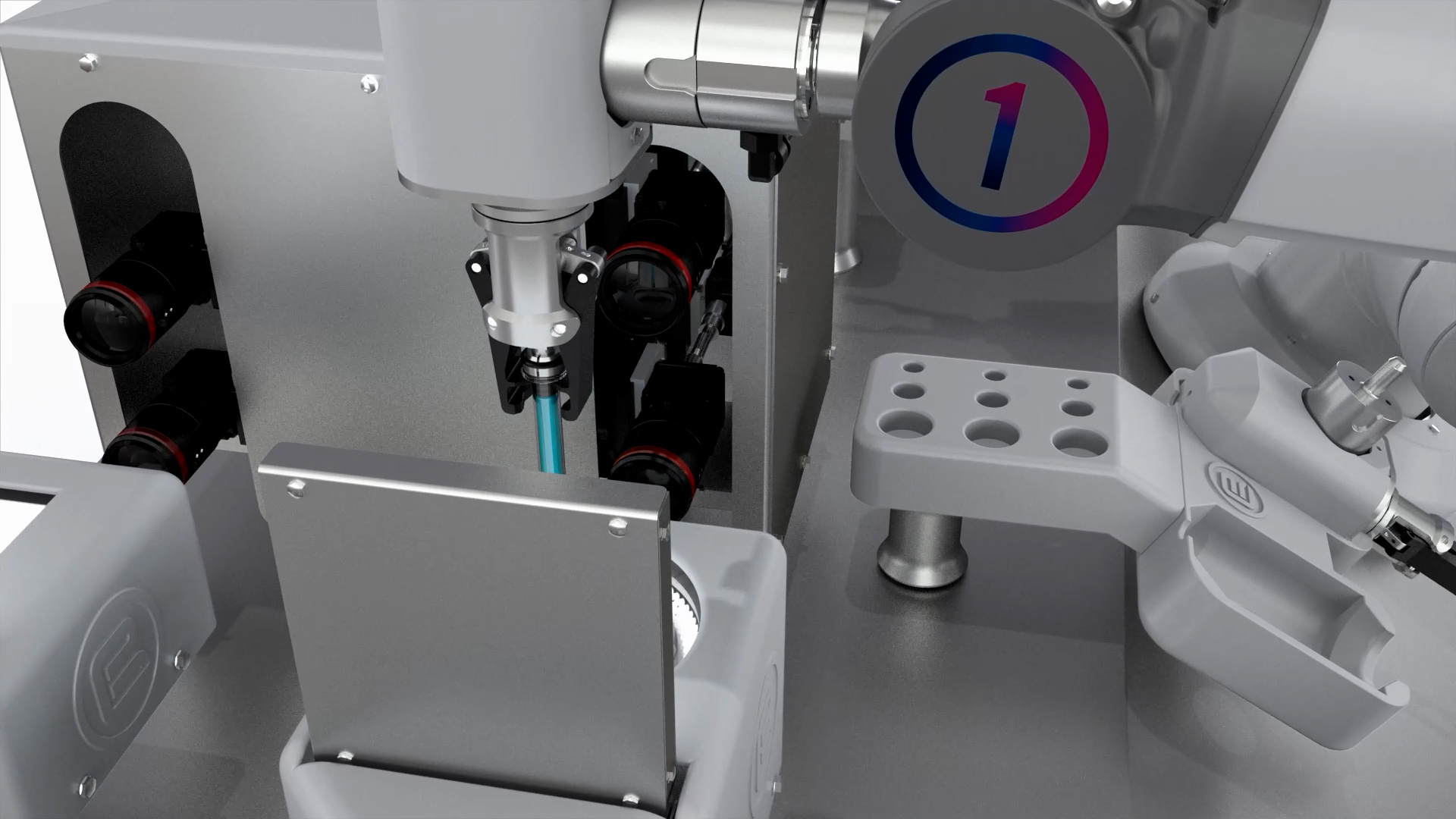

Artificial Intelligence is the core of the machine, it allows to obtain extremely accurate inspection of particle and cosmetic defects, and thus to overcome many past issues and/or false rejects (such as air bubbles, silk-screening on containers, external defect of the containers that are considered non-relevant).

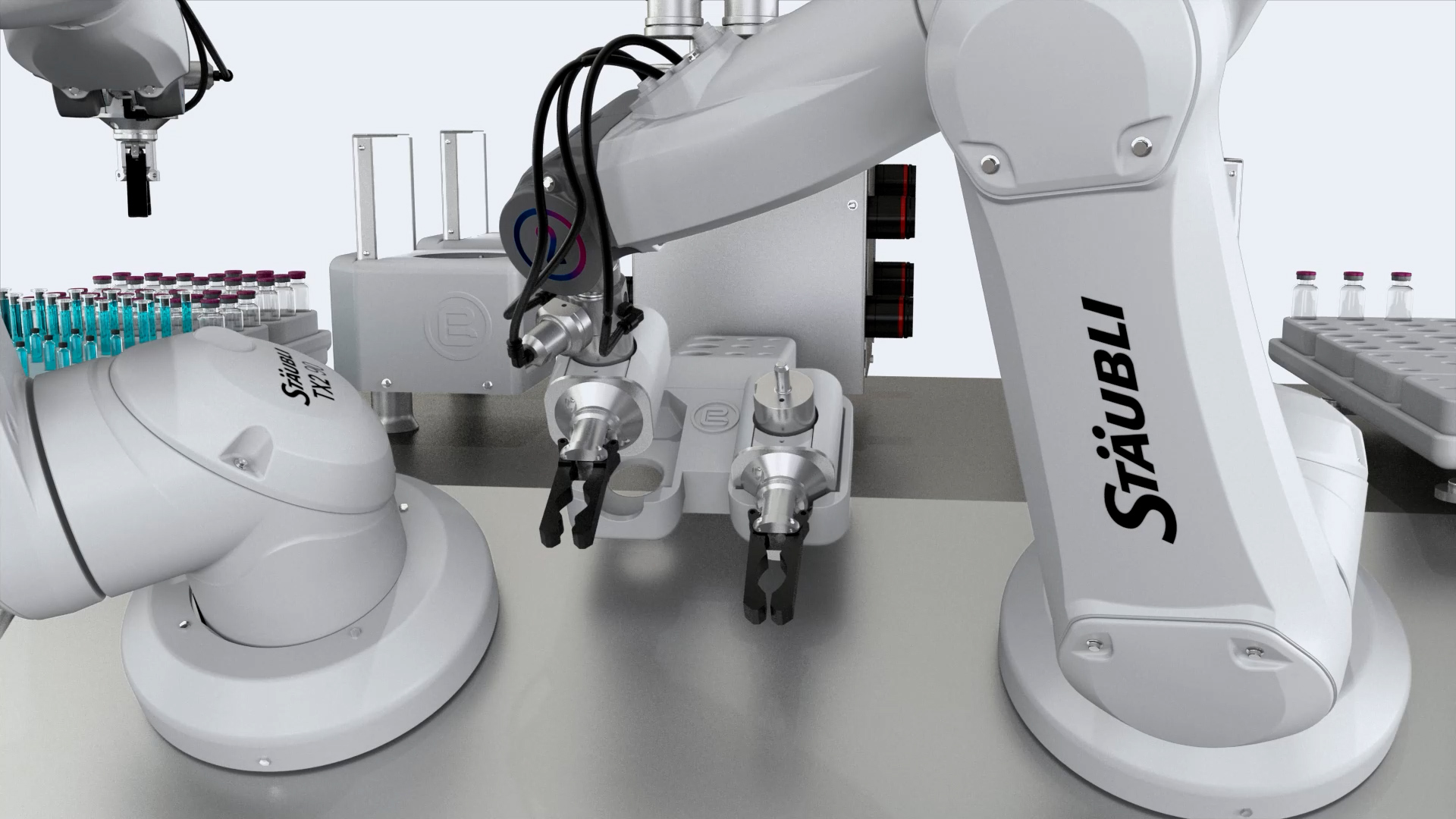

The extremely compact design, combined with the handling flexibility provided by the ROBOTS, makes RTF ROBOX A/I a unique modular machine.

Main features

⦁ Manual or automatic container loading system

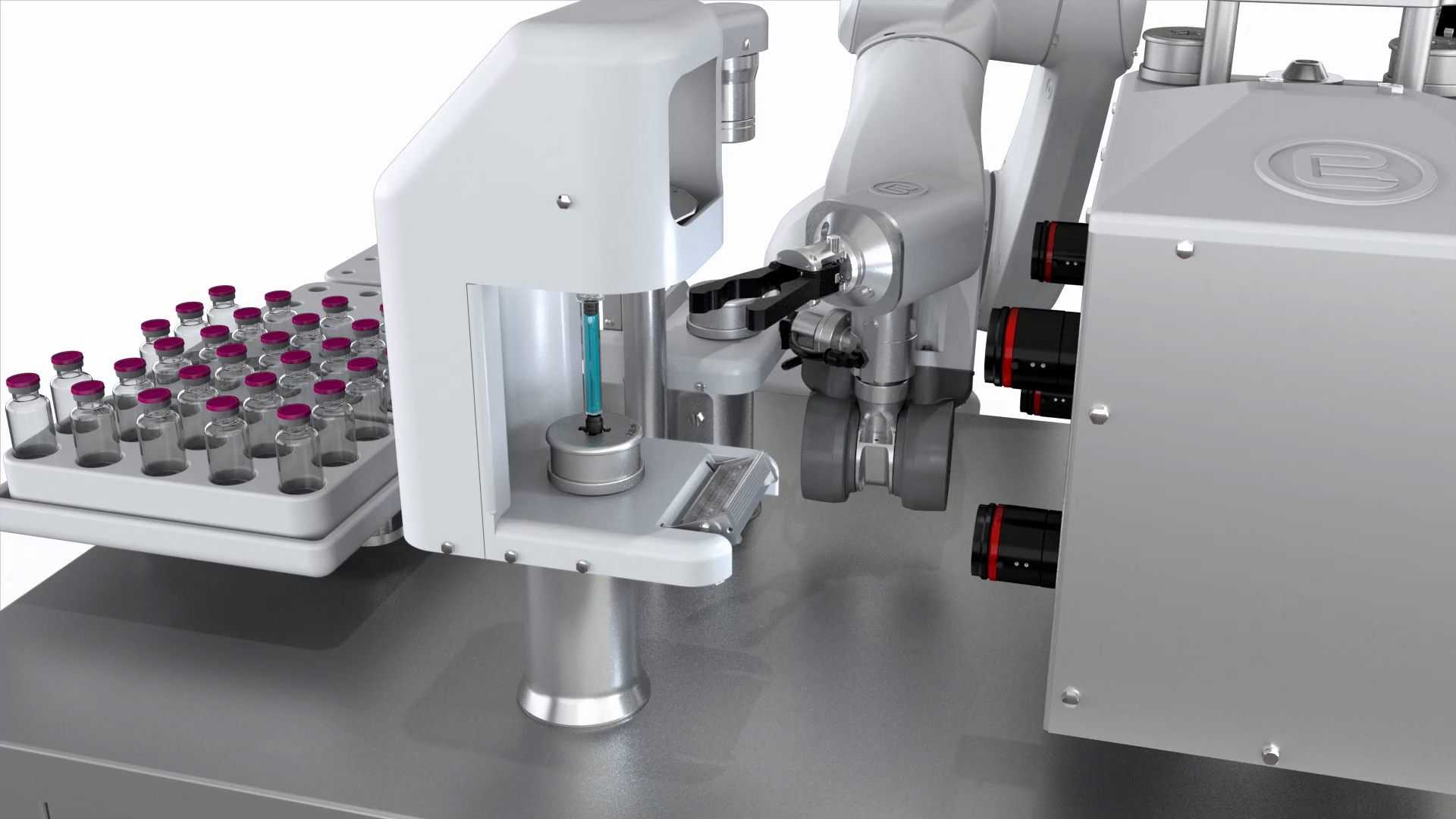

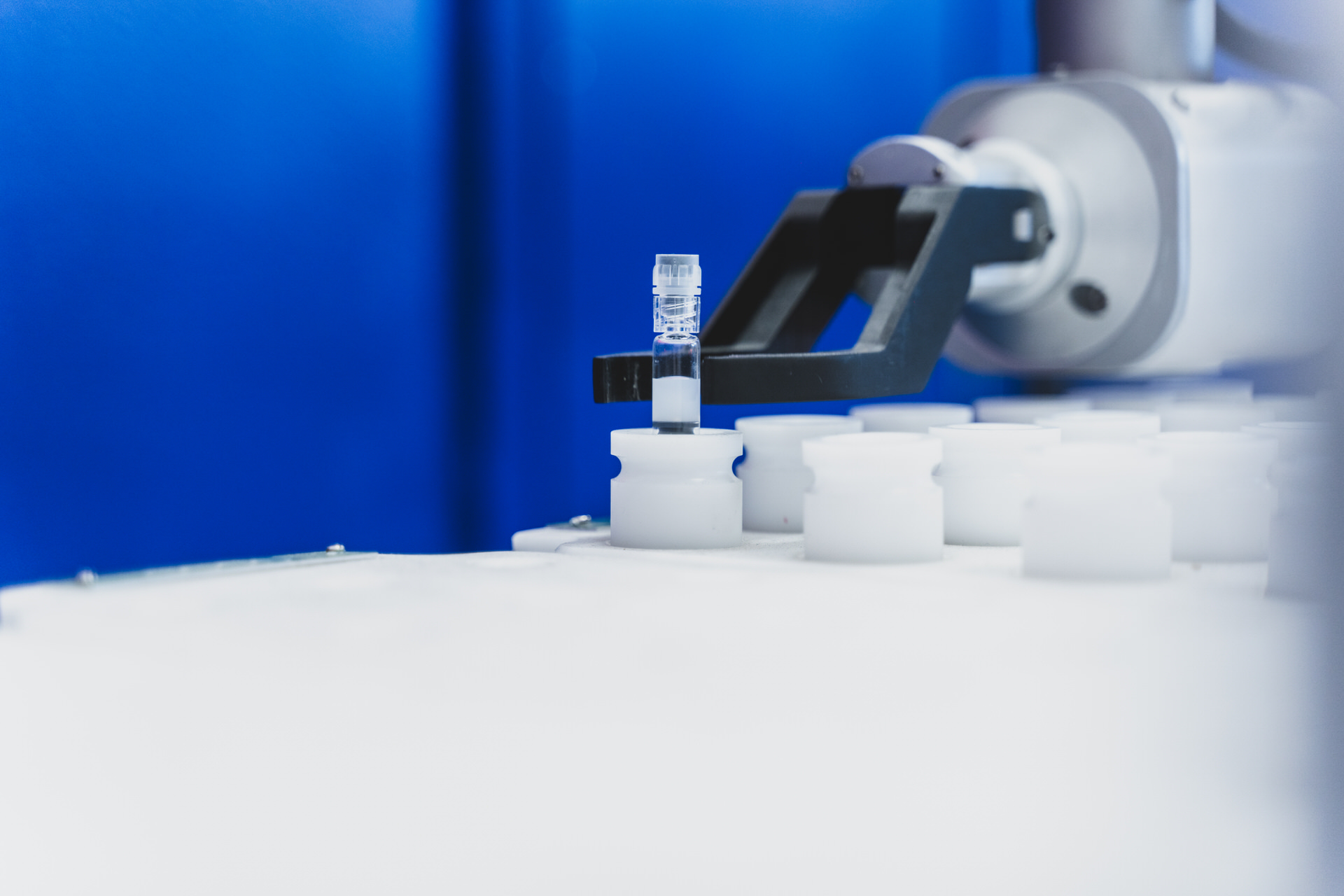

⦁ Container handling robotic system

⦁ N° 8 inspection stations (standard version)

⦁ Possibility of varying the number of inspection stations according to different needs

More features

⦁ Manual or automatic cameras set up

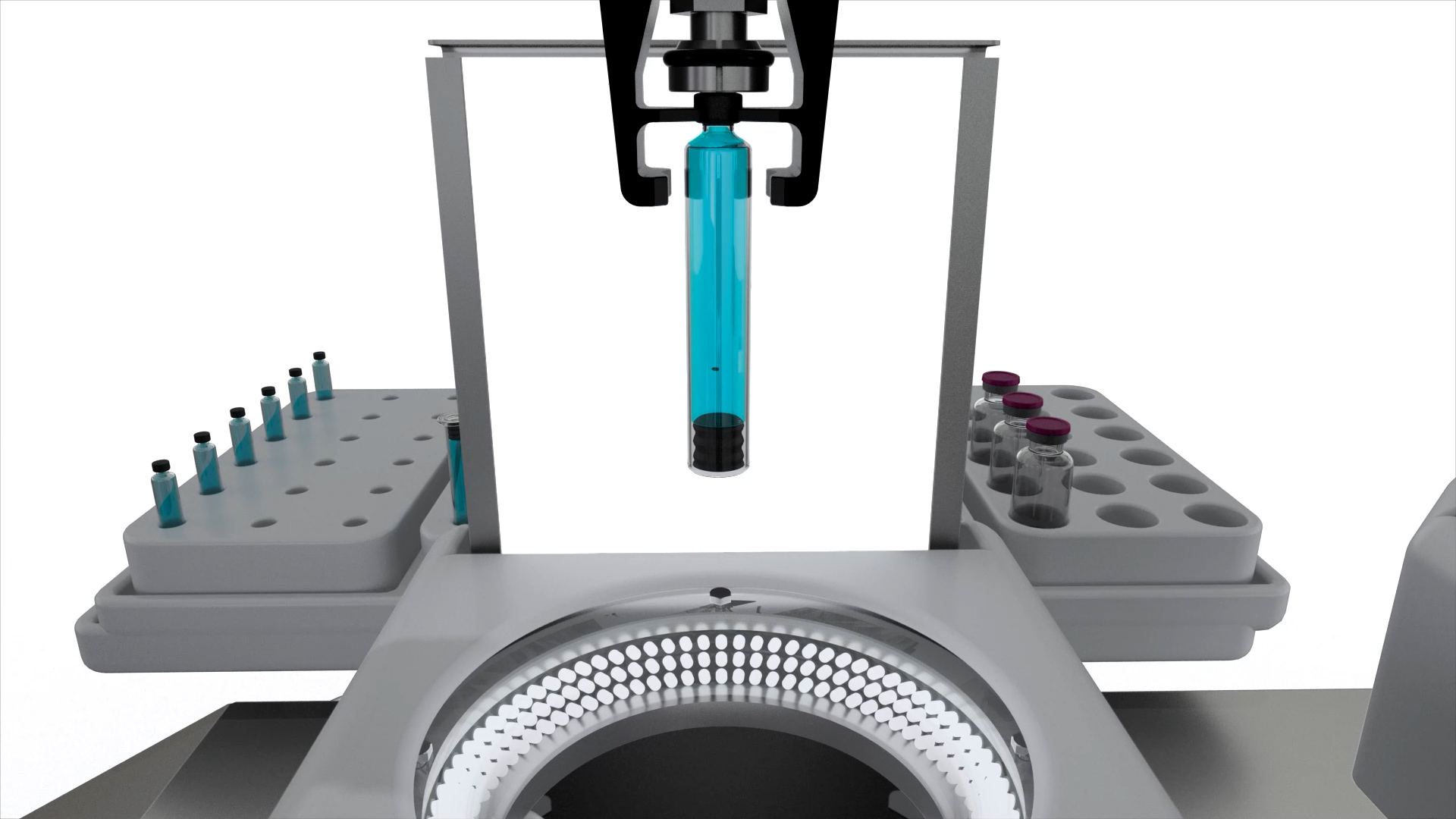

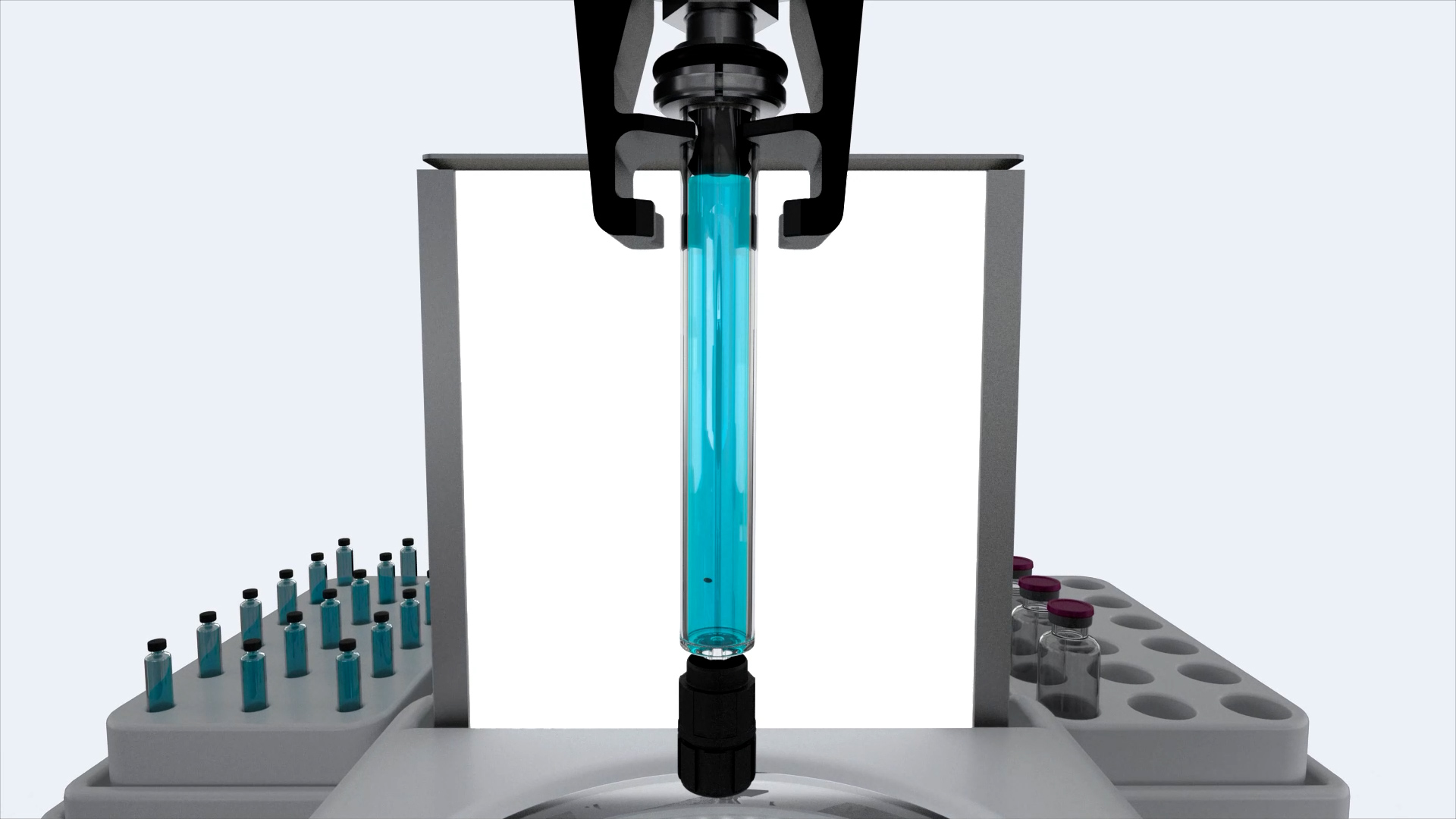

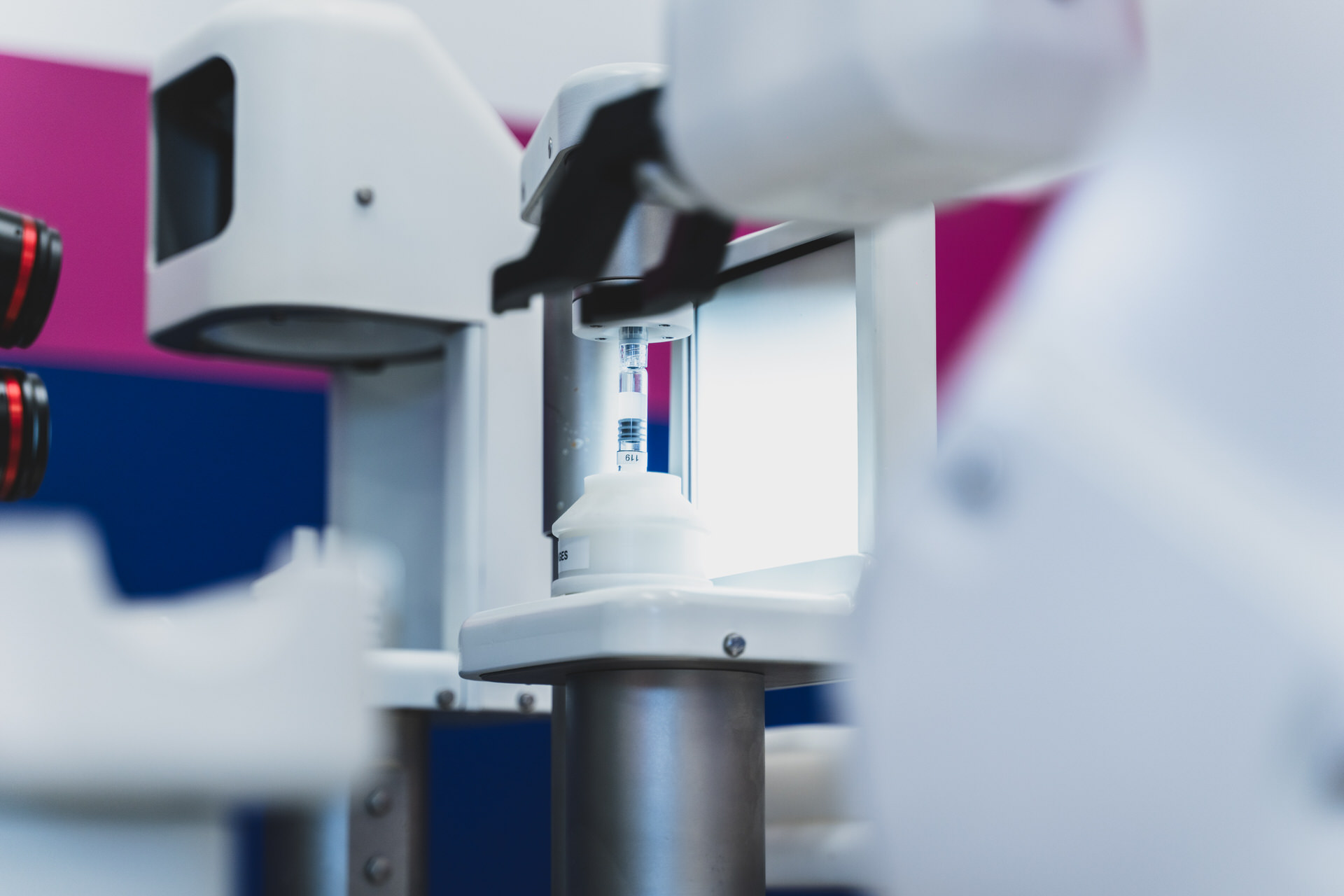

⦁ Liquid particle control:

⦁ Particle control

⦁ Meniscus control

⦁ Heavy particle control

⦁ LYO cosmetic control:

⦁ Lateral control

⦁ Bottom control

⦁ Surface control

⦁ Cosmetic check:

⦁ 100% container body cosmetic control

⦁ Product color control

⦁ Cap/Plunger control

⦁ Flip-Off control

⦁ Flange control

⦁ Needle control

⦁ Vacuum decay (VD) method available.

⦁ High voltage (HV) method available.

⦁ Integrated labeling heads

⦁ Printing of variable data on label

⦁ Control of variable data on label

⦁ Label presence control

⦁ Dedicated reject stations

⦁ No GLASS-TO-GLASS contact

⦁ User-friendly machine interface

Machine Output

6 to 20 BpM

Compatible containers

Case History

Artificial Intelligence Technology

Thanks to our proprietary AI-technology we are able to offer the unmatched ability to recognize, in real time, the presence of particle defects and leaks in both rigids and flexible containers.

Contact us