Overview

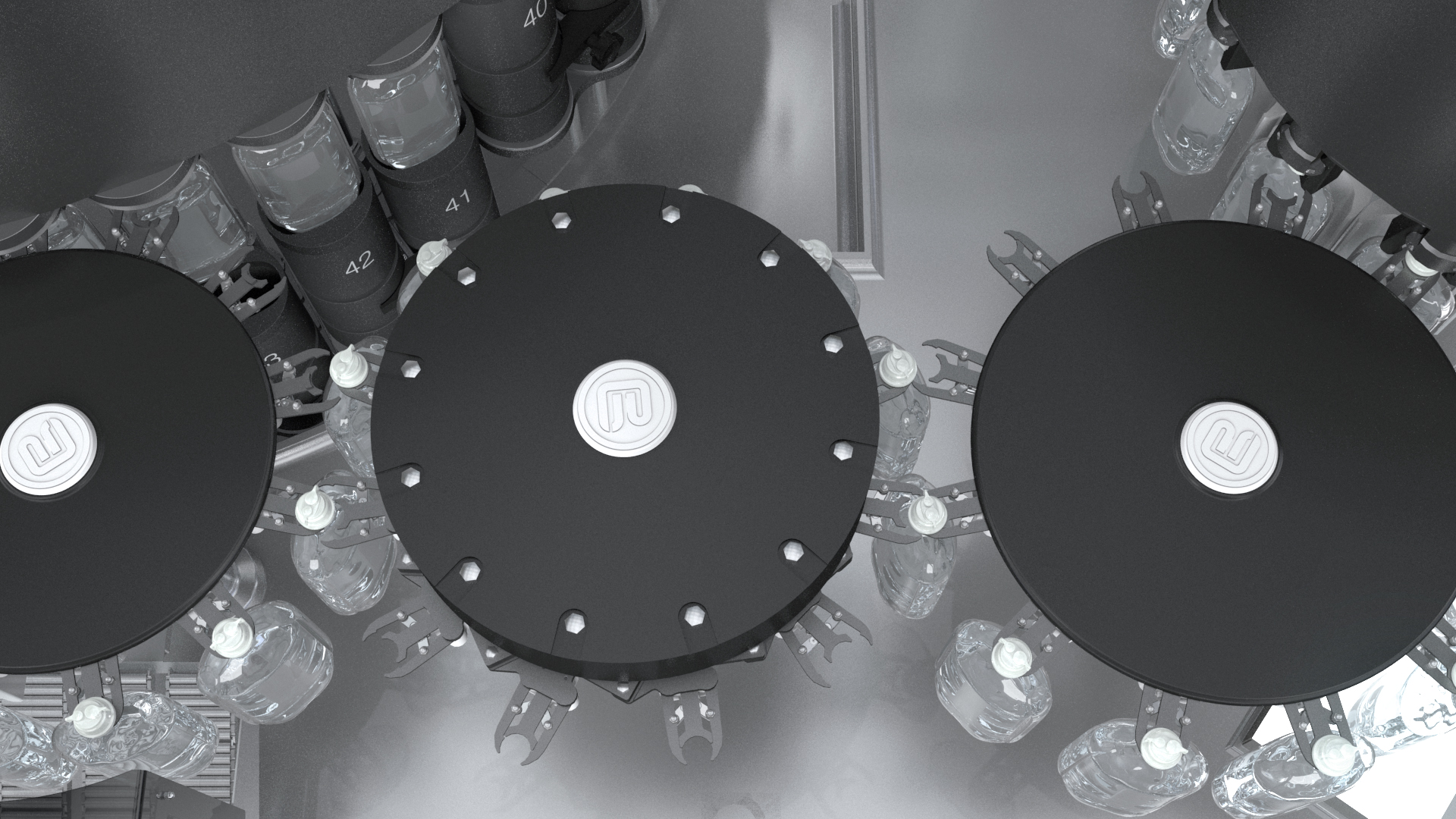

PBL Pharma Division offers an innovative and flexible leak testing machine for PP/PE bottles.

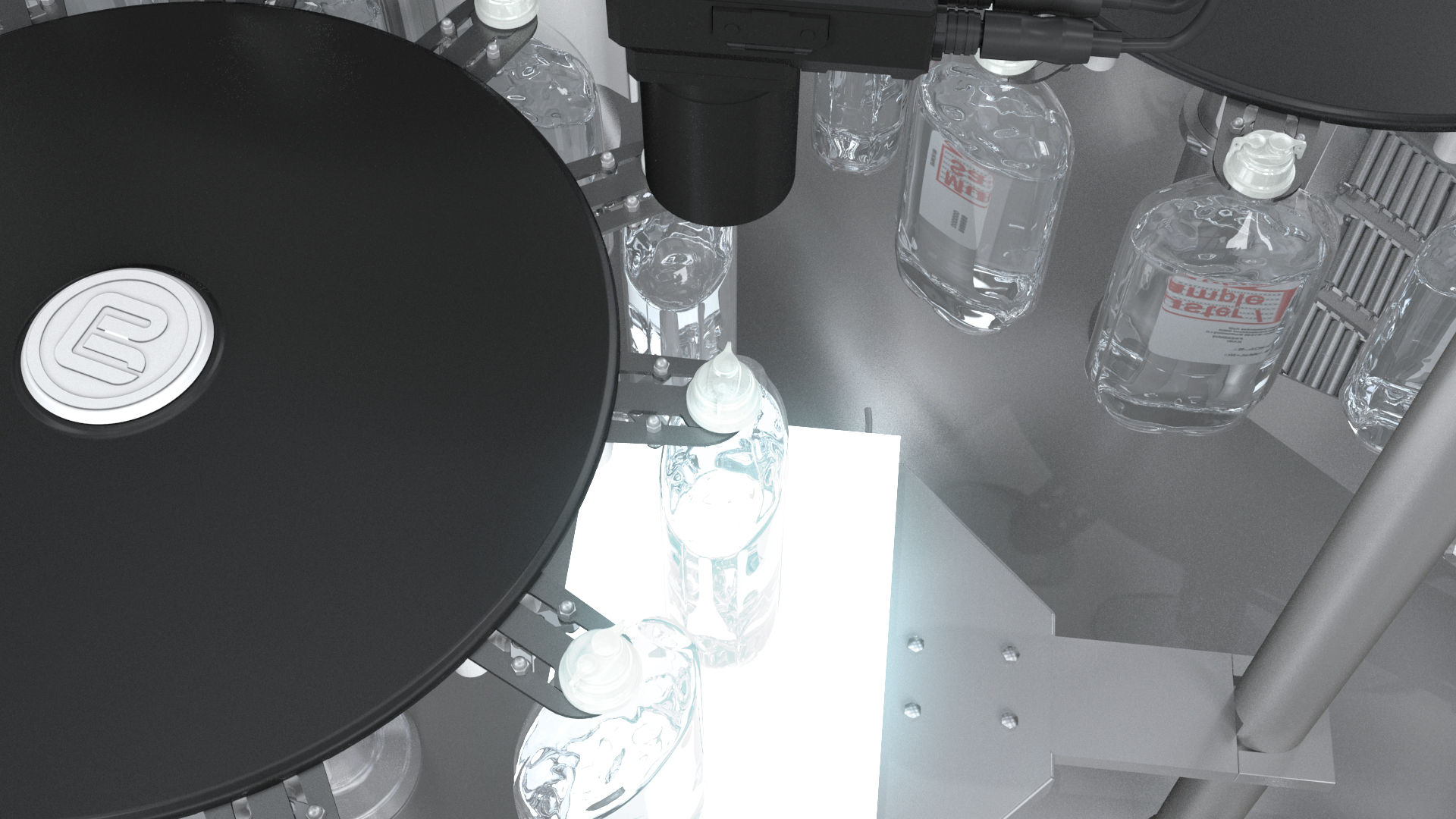

The main objective was to create a machine capable of performing leak tests using a vacuum decay system, with high performance in terms of efficiency and detection of small micro-holes.

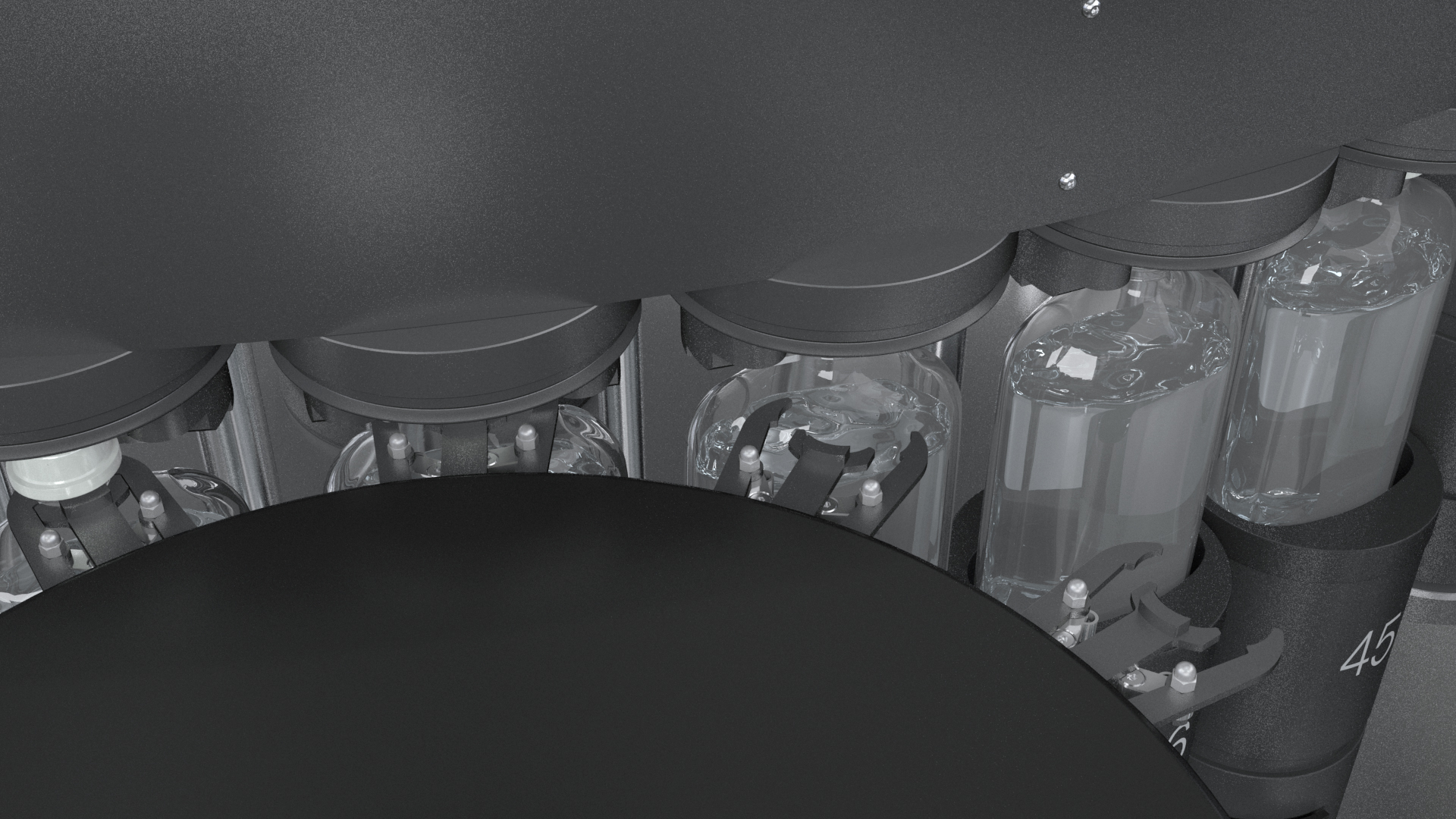

The handling flexibility provided by the automated neck handling system avoids any bottles-to-bottles contact, thus preserving the integrity and quality of the containers by preemptively eliminating any source of defects. There features, together with an extremely compact design, make INTEGRA a unique modular machine.

Main features

• No bottle-to-bottles contact

• Vacuum decay (VD) method available

• Hight Voltage (HV) method available

• Labeling heads integrated

More features

• Label variable batch data printing

• Label variable data control

• Label presence control

• Dedicated rejects stations

• User-friendly machine interface

Machine Output

50 to 300 BpM

Compatible containers

Artificial Intelligence Technology

Thanks to our proprietary AI-technology we are able to offer the unmatched ability to recognize, in real time, the presence of particle defects and leaks in both rigids and flexible containers.

Contact us