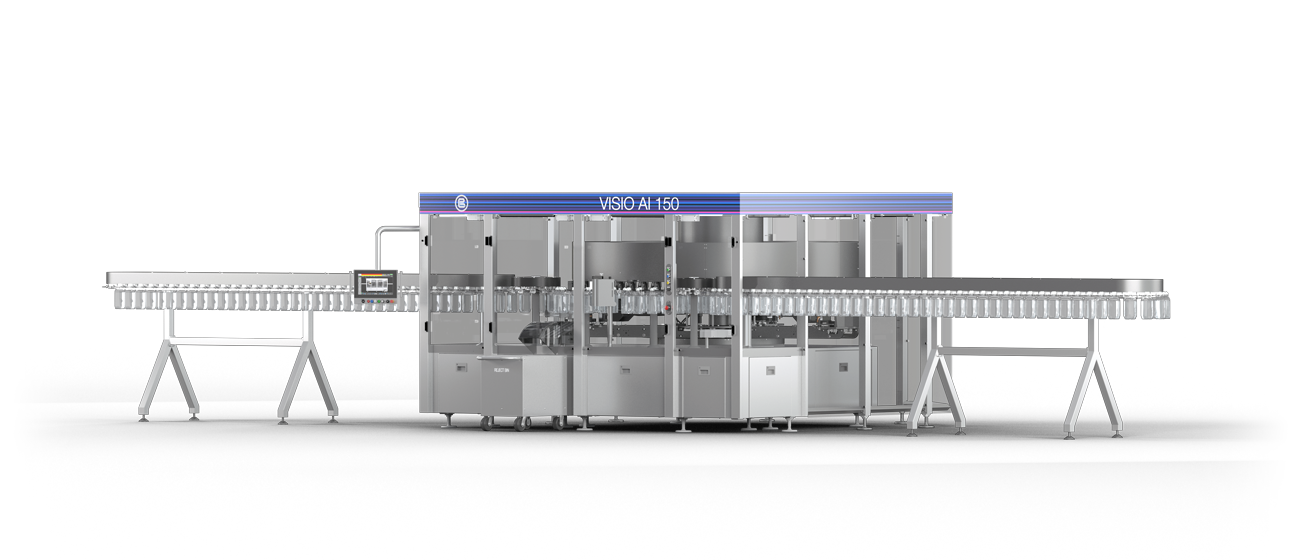

Overview

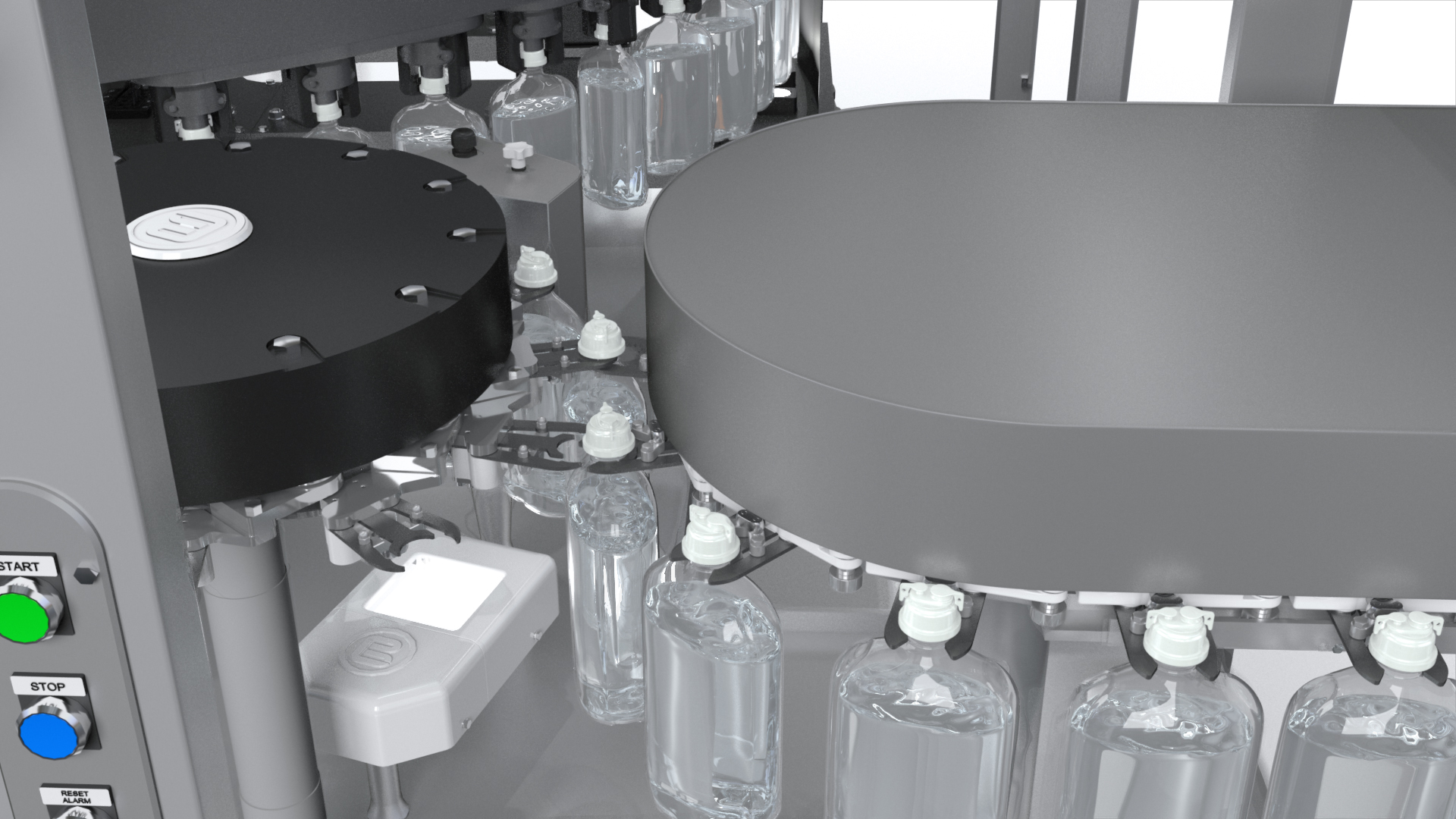

Our Pharma Division offers an innovative and flexible inspection machine for PP/PE bottles.

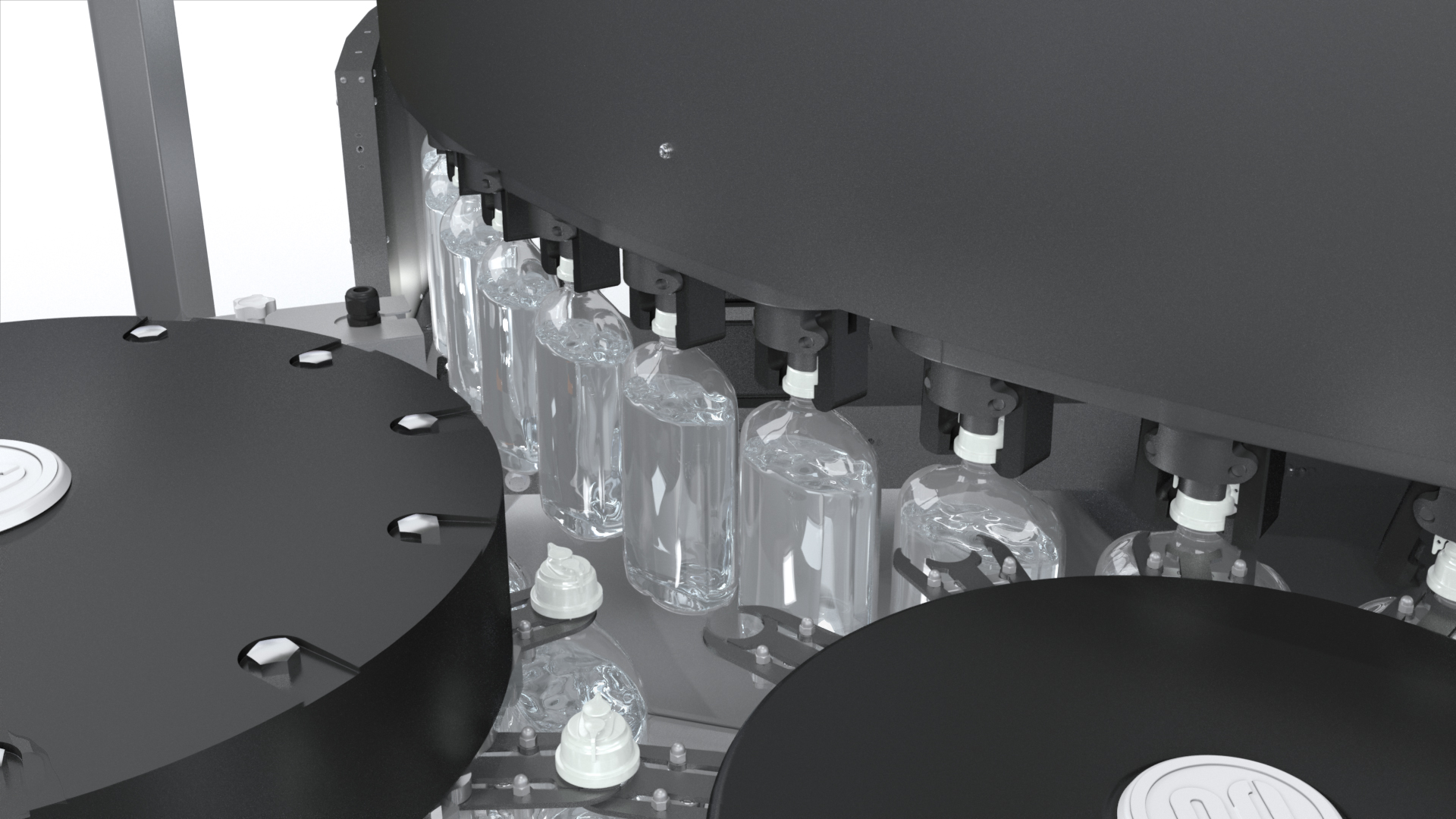

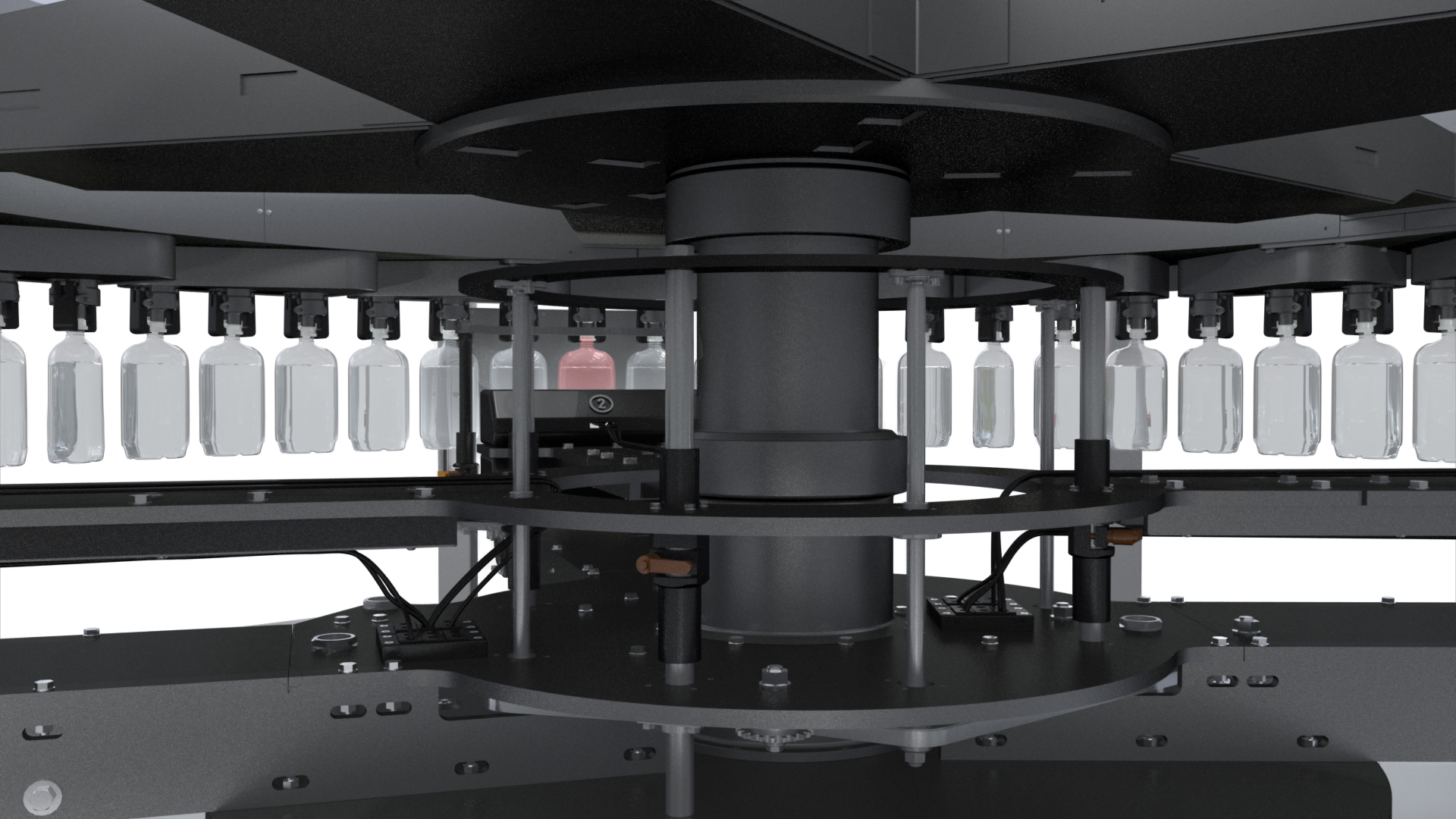

The main goal was to create a machine capable of performing particle and cosmetic inspections all over the container surface. This has been possible thanks to a new neck handling system and two dedicated inspection stations supported by Artificial Intelligence.

Artificial Intelligence is the core of our machine: it allows to obtain an extremely accurate inspection of particle and cosmetic defects, and thus to overcome many past issues and/or false rejects (such as air bubbles, silk-screening on containers, aesthetic defects of the containers that are considered non-relevant).

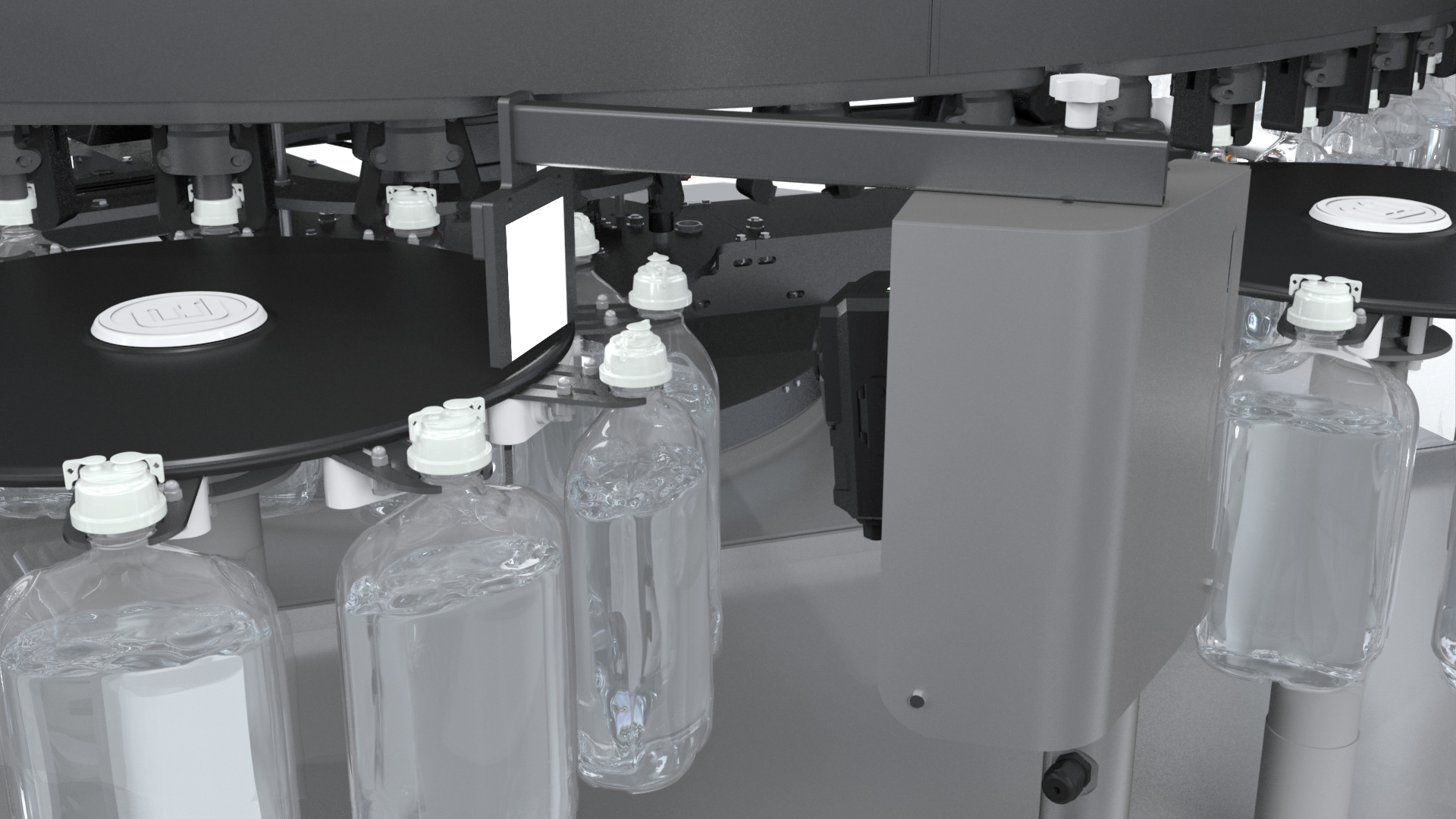

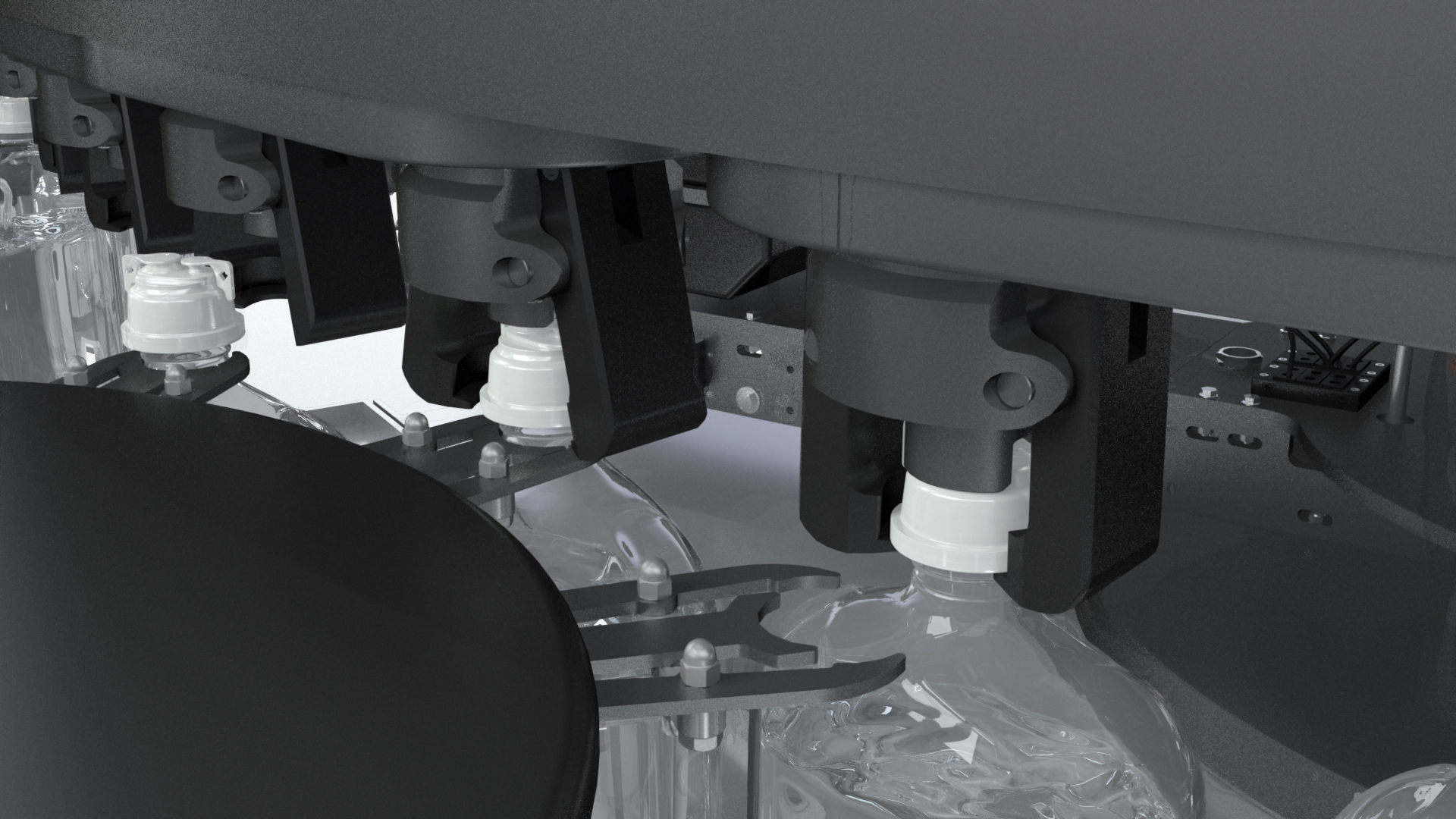

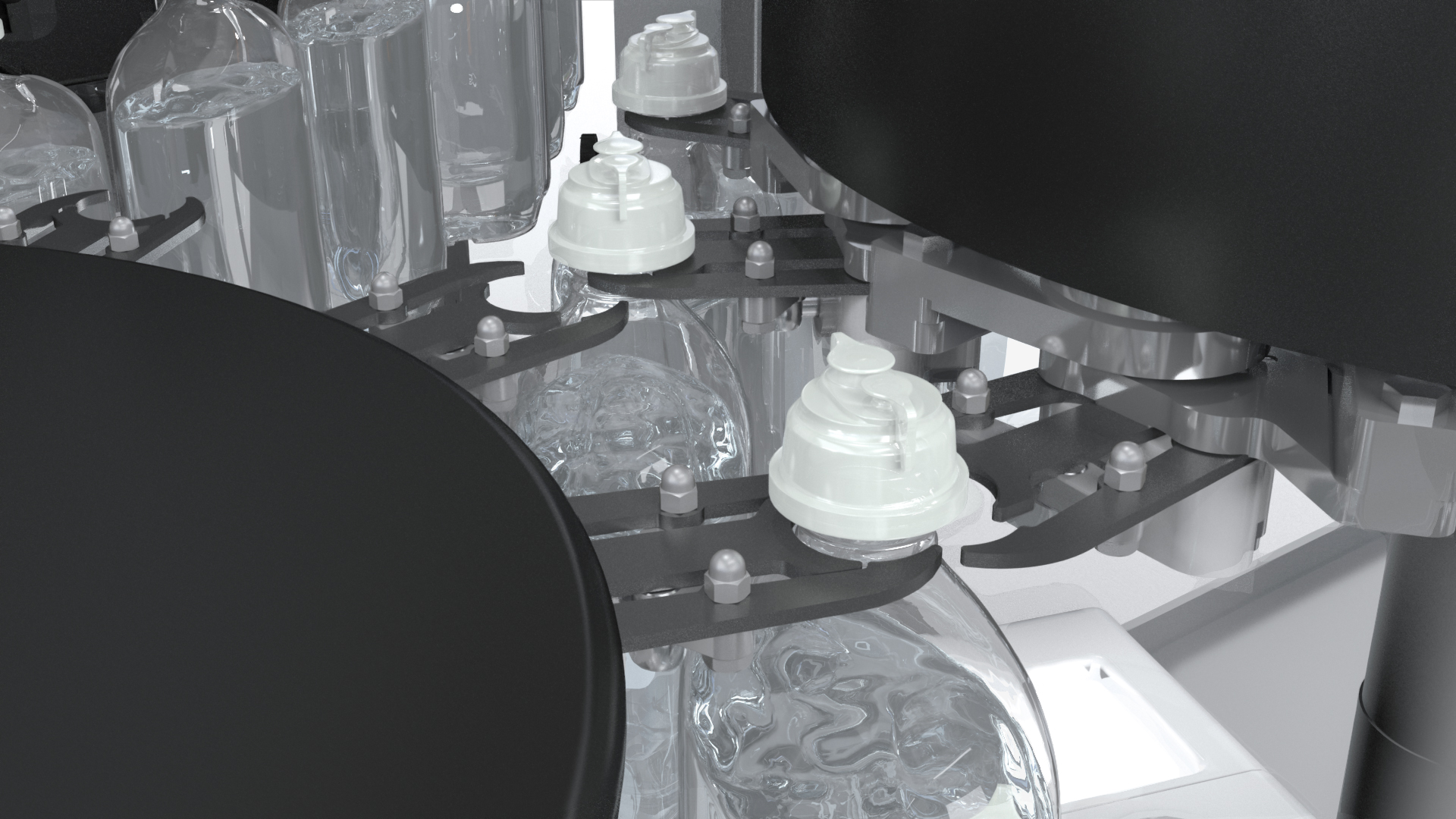

The handling flexibility provided by the automated neck handling system avoids any bottle-to-bottle contact, thus preserving the integrity and quality of the containers by preemptively eliminating any source of defects. These features, together with an extremely compact design, make VISIO a unique modular machine.

Main features

⦁ No bottle-to-bottle contact

⦁ Neck handling direct drive gripper

⦁ Heavy particles inspection station (side A)

⦁ Heavy particles inspection station (bottom)

More features

⦁ Light particles inspecton station 1

⦁ Light particles inspecton station 2

⦁ Light particles inspecton station 3

⦁ Body cosmetic control

⦁ Cap control

⦁ Heavy particles inspection station (side B)

⦁ Automatic rejection unit

⦁ Neck handling conveyor

⦁ Rear illumination system

⦁ Back illumination system

Machine Output

50 to 300 BpM

Compatible containers

Artificial Intelligence Technology

Thanks to our proprietary AI-technology we are able to offer the unmatched ability to recognize, in real time, the presence of particle defects and leaks in both rigids and flexible containers.

Contact us